We understand the challenges faced by manufacturing companies when it comes to creating the best possible production and manufacturing environments. From Hygenic Valves for the food and beverage industry to aseptic applications, we offers valves for a wide range of sites. Alongside our award-winning Evoguard range, we also supply valves from a range of OEM manufacturers including GEA Tuchenhagen, Alfa Laval, Realm, Sudmo, Guth, Eurobinox, Tassalini, Nocado, Keofitt, Ampco and Definox.

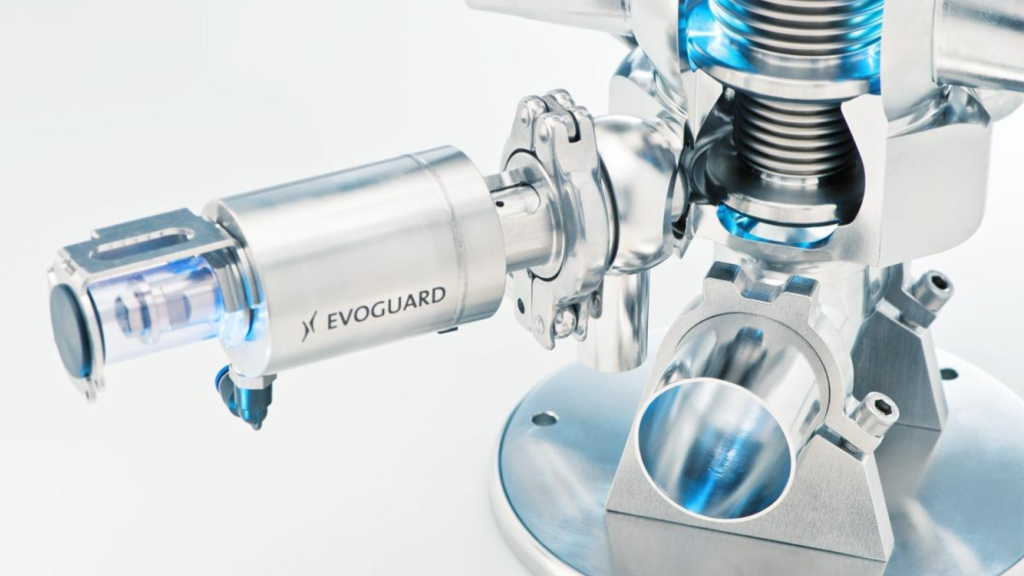

At Unison, we are the sole distributors of Evoguard valves in Ireland. As a subsidiary of Krones, and with decades of experience in the manufacture of valves for line construction, Evoguard specialises in high quality components for use in lines for manufacturing companies of all sectors. Their valves and pumps are renowned for meeting high safety standards and first-class reliability while in continuous operation.

At Unison, we understand that engineering and technologies are continually evolving in manufacturing environments and brands like Evoguard need to react to this changing landscape. In that context, Evoguard deploys innovative technology for valves, valve manifolds and Vessel Dome Fittings used in process and filling technology. Our valves perfectly illustrate first-class KRONES quality at component level.

Manufactured in accordance with the highest quality and hygienic design guidelines, Evoguard is a proven, market-leading brand. Demonstrating high efficiency standards, they also maintain a focus on easy and reliable operation in everyday production. The Evoguard range of cost-effective, modular valves has been developed with busy manufacturing environments in mind.